-

Notifications

You must be signed in to change notification settings - Fork 4

New issue

Have a question about this project? Sign up for a free GitHub account to open an issue and contact its maintainers and the community.

By clicking “Sign up for GitHub”, you agree to our terms of service and privacy statement. We’ll occasionally send you account related emails.

Already on GitHub? Sign in to your account

Hints on the framework design and entry points for integrating the motor parameters estimation using the current control #19

Comments

I am not sure about this. If no low-level speed estimates are available, the proper replacement is a non-causal velocity estimation, that cannot be done in realtime without delay that could affect the estimation. |

|

@traversaro , yes indeed. Sorry for the confusion, I was focusing on the interface for getting the velocity. The idea would be to have a stub that gets the last results from a velocity estimator. That estimator could eventually even be implemented in C++ and running under a different thread. |

|

Perhaps we need to discuss this f2f, but what I meant is that for estimation we should use a non-causal velocity estimation, that could be implemented in matlab. |

|

ok, I get it. Anyway we can discuss further after lunch. |

@traversaro To have clarity, in our case (if I'm not wrong), the joint velocities are obtained as a result of the velocity estimator, however we do not have a measure or an estimate for the motor velocities. But this could be obtained by mapping the joint velocities through the transmission. But, it would be better to not rely on these velocity estimates due to the inherent delay involved in the controller. Hence we would rely on offline non-causal estimation of the velocities and accelerations by applying a savitzy-golay filtering over the joint positions. Please correct me, if I'm wrong ? |

I'm sorry, I'm not in IIT. I could join you through skype, if you're going to have a meeting/discussion on this. |

|

Before using current control, I require to do current control calibration similarly to In order to do that I need to record current measurement that is currently not available in I have some questions regarding this implementation. @nunoguedelha

|

Enabling measurements for specific sensors

I forgot to mention in the initial notes... The compomemt sensors-calib-inertial/src/@SensorDataYarpI/SensorDataYarpI.m Lines 123 to 147 in dacb506

This function maps the sensor types to the Yarp ports where the respective data can be retrieved. The entries to that map are the sensor types you find in the Motion Sequence Profile files like https://github.com/robotology-playground/sensors-calib-inertial/blob/master/src/conf/advanced/lowLevTauCtrlCalibratorSequenceProfile1.m. This way The initial idea was to have an interface of the profile files independent w.r.t. how the ports group the sensor data on iCub, so although there are two labels 'joint' (for joint encoders) and 'jtorq', they both map to the same port on iCub. For some reason I forgot (probably lack of time), I didn't define a label for 'pwm' ad 'mot', but just reused 'joint'. So the option

As you like, I suggest you use ['meas' 'curr'] and on the go, correct the case for 'pwm' and 'mot' (motor q,dq,d2q). Retrieving the data offline from the port

|

|

I am trying to run the The problem may be related to the compilation of the bindings, and doesn't depend specifically on the I am currently at:

I don't get any problem during the compilation. |

|

@lrapetti , could you move this to a new issue please? in order to leave in this one only the tutorial discussion. |

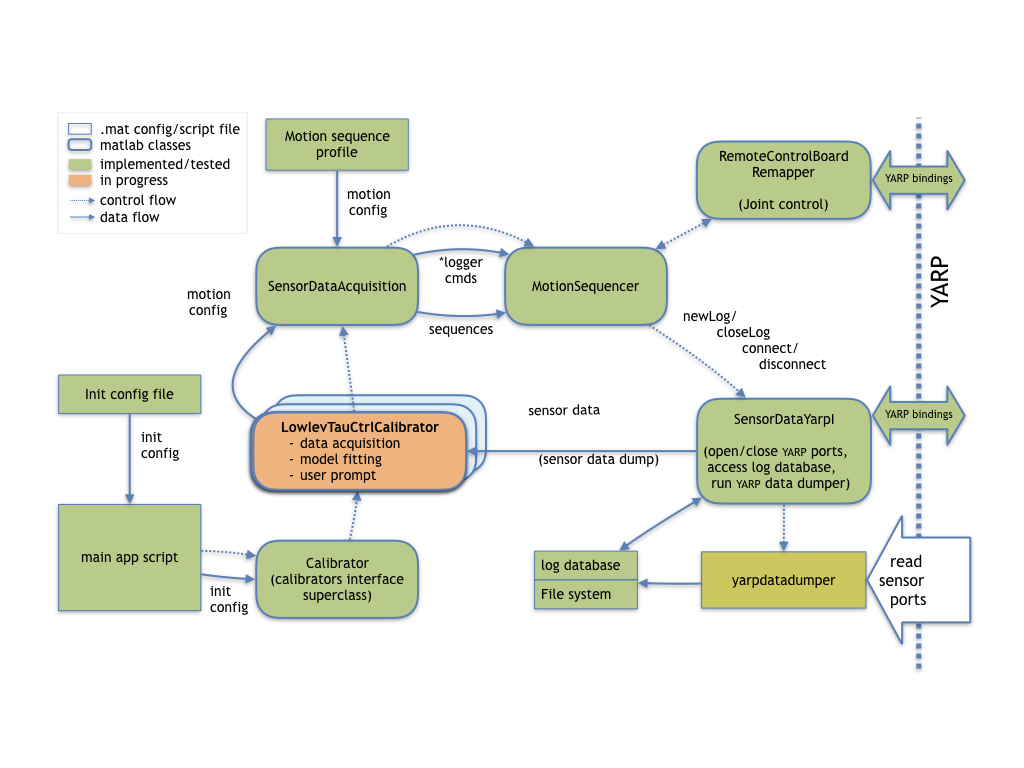

@lrapetti, @prashanthr05, I will depict here the link between the blocks in the framework design diagram below and the code entry points:

General architecture

All the framework is designed following an Object Oriented approach:

Init configuration files

Init config file: src/conf/sensorSelfCalibratorInit.m is the main user interface. The script defines:modelNameandmodelPathdataPathwhere all the logs will be savedcalibrationMapFile. All the paths here are relative, starting from the application folder<repo_ROOT_path>/src/appcalibrateLowLevTauCtrl = true;and the other entries tofalsecalibedParts = {'right_leg'[,'left_leg','right_arm','left_arm']}selects the parts to calibrate;calibedJointsIdxesfine selects the joints for each active part (only the lines relative to selected parts are relevant);sensorDataAcqvalue triggers for each estimation procedure, a new acquisition, the last acquired data, or a specific data log ID. The two later features haven't been tested for the friction/motor parameters estimation. Refer to the comments for more details.Changes for motor current control: you need an additional entry in the task checklist, and the respective block with the parameters

calibedParts,calibedJointsIdxesandsensorDataAcq.Motion Sequence Profiles:Each of these define the target joint positions sequences to execute while acquiring the desired data, along with the list of sensors to get the data from. The profile1 defines the sequences for the friction parameters estimation, while profile2 targets the motor parameters estimation.

Each structure defining the joints position sequence has two fields:

labels(the headers) andval(the values). There are two types of structures:- one defining the home position:

homeCalib- another defining a sequence for each part

We will focus on the second type. We can take as an example the left arm sequence:

sensors-calib-inertial/src/conf/advanced/lowLevTauCtrlCalibratorSequenceProfile1.m

Lines 35 to 42 in dacb506

Each column defines a task (motion control, sensor data acquisition, control mode switch, ...), and each line in the

valfield section defines a time step in the sequence. Most often, each column header (for instance{'ctrl','pos','left_arm'}') defines respectively: an action, an action parameter, a target part.NAstands for Not Applicable and results in no action. Let's describe each column in this example over the two time steps.First step:

sensors-calib-inertial/src/conf/advanced/lowLevTauCtrlCalibratorSequenceProfile1.m

Line 40 in dacb506

mode) to position control mode (keywordctrl)ctrl, positionposrelative to theleft_armis set tohomeCalib.val{1}, velocityvelis set torepmat( 4,[1 7])=> go to position that position (vector for the left arm 7 DoFs) with maximum velocity 4 degrees/smeasfrom joint encodersjointand joint torquesjtorqon theleft_armare set tofalse=> this step is just for positioning the armcolumn 7: irrelevant.

Second step:

sensors-calib-inertial/src/conf/advanced/lowLevTauCtrlCalibratorSequenceProfile1.m

Line 41 in dacb506

promptStrto the usermode) to PWM control mode (keywordpwmctrl)measfrom joint encodersjointand joint torquesjtorqon theleft_arm('true')pwmctrl), set the PWM (pwm) parameter value to 0 for the motor namedmotor(before this script is run, 'motor' is set to the joints/motors group being calibrated).Changes for motor current control: replace the

pwmctrlmode by a new modecurrctrl, and the parameterpwmby a new parametercurr. These parameters are processed in theMotionSequencerclass methods. Refer to the next section for more details.robots-configuration/hardware/mechanicals) that cannot be properly retrieved from the robot interface yet:fullscalePWM,Gearbox_M2J(torque gearbox ratio from motor to joint),matrixM2J(motor to joint coupling matrix). TheGearbox_M2Jis used here:sensors-calib-inertial/src/@LowlevTauCtrlCalibrator/calibrateSensors.m

Line 90 in dacb506

The Yarp port naming rules and the hardware transmission parameters are already defined for iCub and don't require any change except if you're using another robot. The current information should already be logged in the

stateExtport.Main app, calibrator and motion sequencer classes

LowlevTauCtrlCalibratoris the main class driving the friction and motor parameters estimation procedures.MotionSequencerclass triggers the ports open/close commands ('run' method) and processes the motor control parameters (runandseqMap2runnermethods) extracted from the sequences defined in the sequence profiles mentioned in the previous section.Changes for motor current control: add the new control mode

currctrlhandling. The existing modepwmctrlis handled in the below code sections:sensors-calib-inertial/src/@MotionSequencer/seqMap2runner.m

Lines 76 to 82 in dacb506

(A similar section should be added for the current control mode

currctrl)sensors-calib-inertial/src/@MotionSequencer/run.m

Lines 82 to 110 in dacb506

(A similar section should be added for the current control mode

currctrl, replacing theMotorPWMcontrollerby a new current controller).Motor control interface

The class

RemoteControlBoardRemapperwraps the bindings for creating the remote control board remapper device and get the motor interface for changing the control mode or setting the PWM (or the same way, the current).setMotorsPWM(...)is a good example on how to get an interface likeIPWMControlto set desired motor parameters:sensors-calib-inertial/src/@RemoteControlBoardRemapper/setMotorsPWM.m

Line 9 in dacb506

Changes for motor current control: A similar interface should be created for the current control.

Note on the motor velocity measurement

@prashanthr05, in case the motor velocity measurement is not provided by the hardware, you should stub the respective method

getMotorEncoderSpeedsin the remapper, with a code that estimates the velocity from other measurements (also considering the gearbox ratio).The text was updated successfully, but these errors were encountered: